You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My kind of BTTF MAG project

- Thread starter Jewan

- Start date

RVLF

Sr Member

Yes, but they are here. And on some shots you really see them. Specially on the shoes of the "power laces" scene. And cavx is right about the ribs of the v2 and the hcs... Too big. On my build up project i made them with only one layer of tiny foam, and they pop up too much. If you add them, you should use some piece of fabric or something really thin.

some classic pictures :

The ribs are visible depending of the lighting. When lightened from the front, you'll see almost nothing, but from the sides the shadows are casted and the ribs are more visible.

some classic pictures :

The ribs are visible depending of the lighting. When lightened from the front, you'll see almost nothing, but from the sides the shadows are casted and the ribs are more visible.

Last edited:

DragonGalvy

Sr Member

Flatter ribs look better than the bulging ribs these V2s have. These new HCs with their smooth sides looks way better than the previous versions with their ribs.

If only they'd only used the same amount of foam as the V2's everywhere else..... was kind of disappointed with the HC's straight out of the box, but I remember opening the box of the V2's years ago and going 'oh yeah!' - even the people at work who didnt know anything about sneakers (because I had them delivered to work as I was there Monday to Friday then) thought they were cool and some even recognised what they were supposed to be.

cavx

Master Member

If only they'd only used the same amount of foam as the V2's everywhere else..... was kind of disappointed with the HC's straight out of the box, but I remember opening the box of the V2's years ago and going 'oh yeah!' - even the people at work who didnt know anything about sneakers (because I had them delivered to work as I was there Monday to Friday then) thought they were cool and some even recognised what they were supposed to be.

Yes I still remember that feeling. I even had that for the original V1s and even my MPs back in late 2010. I think it is the SWOOSH missing on these shoes that takes the WOW away from the experience.

Re-worked the patterns again. I think this is ready for conversion to DXF.

Attachments

Last edited:

RVLF

Sr Member

Re-worked the patterns again. I think this is ready for conversion to DXF.

http://www.therpf.com/attachment.php?attachmentid=577435&d=1452775635

Are you going to print it in 3D ?

cavx

Master Member

Are you going to print it in 3D ?

No. I will make the master parts from rigid materials like Perspex which will be laser cut from the DXF file I will create from this Sketch Up file.

This file will be able to be scaled for any size, but there is still some work to finalize on some parts of the sole/heel cup etc plus the creation of new clear parts.

Attachments

Last edited:

No. I will make the master parts from rigid materials like Perspex which will be laser cut from the DXF file I will create from this Sketch Up file.

http://www.therpf.com/attachment.php?attachmentid=577663&d=1452820008

This file will be able to be scaled for any size, but there is still some work to finalize on some parts of the sole/heel cup etc plus the creation of new clear parts.

are you still planing to mold and cast the heel cup, mid sole, clear sole, and ankle bubble and sell them as a kit ? or something like that ?

cavx

Master Member

are you still planing to mold and cast the heel cup, mid sole, clear sole, and ankle bubble and sell them as a kit ? or something like that ?

I have considerable expense to make the parts for myself, so if others want castings, then yes as it helps re-coupe the costs.

Just ordered a new 9 CFM vacuum pump which will be a huge upgrade from my current 3CFM. From there I will have a new larger chamber made up. I'll probably sell off the old pump/chamber as this one will also serve as reverse vacuum forming rig.

I have considerable expense to make the parts for myself, so if others want castings, then yes as it helps re-coupe the costs.

Just ordered a new 9 CFM vacuum pump which will be a huge upgrade from my current 3CFM. From there I will have a new larger chamber made up. I'll probably sell off the old pump/chamber as this one will also serve as reverse vacuum forming rig.

Alright ! hope to see them soon ! I'm so interested in this ! it's going to be a huge step towards more accurate mags!

cavx

Master Member

Alright ! hope to see them soon ! I'm so interested in this ! it's going to be a huge step towards more accurate mags!

I have no time frame on this. I need to get all the gear up and running before I can even think about making new parts.

Take all the time it's no problem something like this will me lots of prep and time !I have no time frame on this. I need to get all the gear up and running before I can even think about making new parts.

cavx

Master Member

Take all the time it's no problem something like this will me lots of prep and time !

I am going to do the tape method of 3D shape to 2D pattern on the Heel Cups soon. Jewan's patterns is symmetrical. MitasTouch pointed out that the wings are not symmetrical and the V2s have this non symmetrical layout the wrong way around. So that needs correcting ASAP.

Would be really cool if I could incorporate my letters into the pattern for the new mold. I will also need to finalize the new larger bubbles too.

cavx

Master Member

New Heel Cup and new larger bubble is pretty much done.

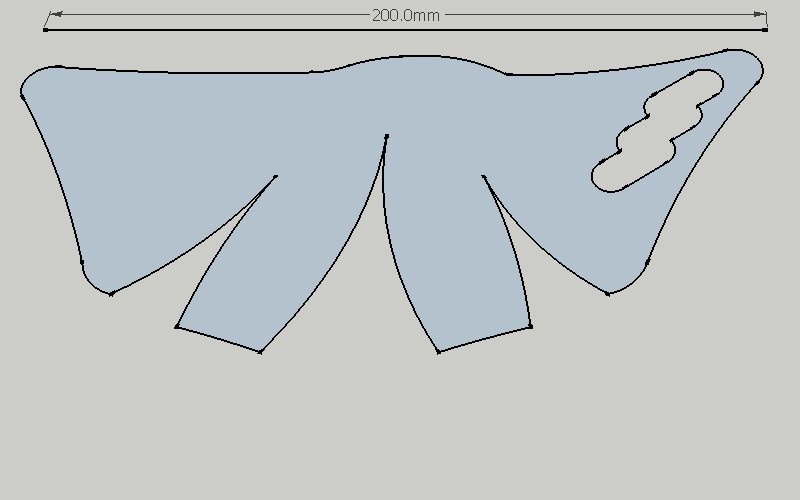

The 1st step is to convert the complex 3D shape to a flat 2D shape.

This was done by placing lots of small pieces of masking tape all over the heel cup, then peeling it of. I had to make some cuts into the tape to allow it lay flat. I then placed the tape along side as scale reference and imported this image into Sketch Up for tracing.

And this is what it came out looking like.

Note I have also correct the shape to be non-symmetrical and reversed the wings so the final will better represent the real part. After doing all this, I releasized that bubble cutout of not quite right and will need revising. Tomorrow. It is past mid-night here now.

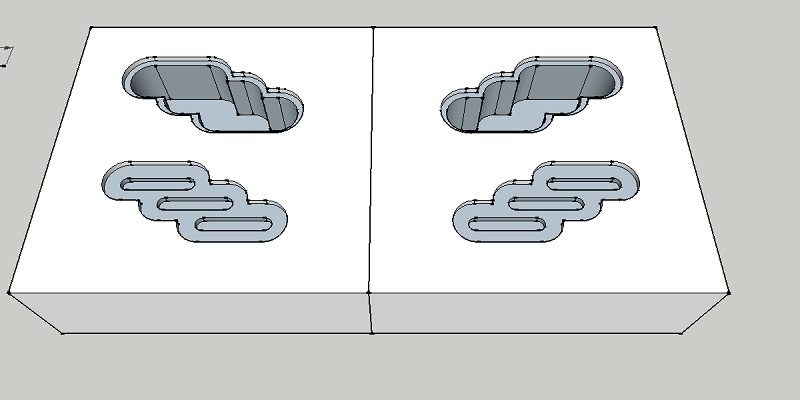

And the new bubble

This will be converted into a STL file for CNC machining. I am making the cutouts on this model as female because it is more cost effective to cut three slots than it is to remove massive amounts of material to leave 3 ridges. I can mold and cast a male part to make my new molds like I did with the lettering.

The 1st step is to convert the complex 3D shape to a flat 2D shape.

This was done by placing lots of small pieces of masking tape all over the heel cup, then peeling it of. I had to make some cuts into the tape to allow it lay flat. I then placed the tape along side as scale reference and imported this image into Sketch Up for tracing.

And this is what it came out looking like.

Note I have also correct the shape to be non-symmetrical and reversed the wings so the final will better represent the real part. After doing all this, I releasized that bubble cutout of not quite right and will need revising. Tomorrow. It is past mid-night here now.

And the new bubble

This will be converted into a STL file for CNC machining. I am making the cutouts on this model as female because it is more cost effective to cut three slots than it is to remove massive amounts of material to leave 3 ridges. I can mold and cast a male part to make my new molds like I did with the lettering.

Attachments

New Heel Cup and new larger bubble is pretty much done.

The 1st step is to convert the complex 3D shape to a flat 2D shape.

http://www.therpf.com/attachment.php?attachmentid=577838&d=1452866070

This was done by placing lots of small pieces of masking tape all over the heel cup, then peeling it of. I had to make some cuts into the tape to allow it lay flat. I then placed the tape along side as scale reference and imported this image into Sketch Up for tracing.

And this is what it came out looking like.

http://www.therpf.com/attachment.php?attachmentid=577840&d=1452866115

Note I have also correct the shape to be non-symmetrical and reversed the wings so the final will better represent the real part. After doing all this, I releasized that bubble cutout of not quite right and will need revising. Tomorrow. It is past mid-night here now.

And the new bubble

http://www.therpf.com/attachment.php?attachmentid=577839&d=1452866115

This will be converted into a STL file for CNC machining. I am making the cutouts on this model as female because it is more cost effective to cut three slots than it is to remove massive amounts of material to leave 3 ridges. I can mold and cast a male part to make my new molds like I did with the lettering.

If your wanting to put the Nike mag letters on the heel cup just make a mold to the heel cup and glue the letter you have already and make a mold of that, I remember cloneprops did something like this.

here's an image of the mold cloneprops made, here's the link the the thread http://www.therpf.com/showthread.php?t=140997

here's an image of the mold cloneprops made, here's the link the the thread http://www.therpf.com/showthread.php?t=140997DragonGalvy

Sr Member

nope, the huge amounts of foam in the HC's totally screwing up the shape was my disappointment. a swoosh is easy to cut and stick on, fixing the shape, not so much. I will attempt to at least fix the toe after I get my shed/workshop built.Yes I still remember that feeling. I even had that for the original V1s and even my MPs back in late 2010. I think it is the SWOOSH missing on these shoes that takes the WOW away from the experience.

cavx

Master Member

If your wanting to put the Nike mag letters on the heel cup just make a mold to the heel cup and glue the letter you have already and make a mold of that, I remember cloneprops did something like this.

View attachment 577846 here's an image of the mold cloneprops made, here's the link the the thread http://www.therpf.com/showthread.php?t=140997

Will see how this pans out. I have a long road ahead of me. So not 100% sure how I will do this yet.

nope, the huge amounts of foam in the HC's totally screwing up the shape was my disappointment. a swoosh is easy to cut and stick on, fixing the shape, not so much. I will attempt to at least fix the toe after I get my shed/workshop built.

That is a bit of bummer. I was hoping these might be OK with a collar extension and sock toe, and of course some wide, clear soles.

@cavx, I'm not sure if it's too late to say this, but I just looked at the picture of the MAGs I posted a page back and noticed that the ankle bubble curves with the heel cup.

Like the heel cups, these are going to a 3 stage just to make a proper master part, so it may be possible to curve the outer edge. I will know more once I speak to the machinist to

see what tools he has. I want him to use a rounded cutter if has one as well so the first gen parts are rounded and I don't have to sand the parts round.

DragonGalvy

Sr Member

Well, I think if I had been able to get them before the V2's I might have been more impressed. You expect products to improve with time. Not to worry. They did cost significantly less.That is a bit of bummer. I was hoping these might be OK with a collar extension and sock toe, and of course some wide, clear soles.

cavx

Master Member

Not to worry. They did cost significantly less.

Because they are supposed to make these as small as US5 or 6, would be cool for the wife. She'd wear them. So basically a 2 for 1 deal at their price.

Similar threads

- Replies

- 1

- Views

- 780

- Replies

- 0

- Views

- 1,146