Thanks for another video Stu, can't get enough of these!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building The ANH 5'Millennium Falcon

- Thread starter eagle1

- Start date

Thank you so much Dimitri, means much to me!.Thanks for another video Stu, can't get enough of these!

Cheers Joberg. Computer images work well ditectly off the screen when scaling is taken into account.Fantastic workmanship mate...and I do the same as you: for my 2001 Docking Bay, I blew the pic on the computer to the right size (15") and took direct measurements from there. Worked very well

Ha, thanks man!. When I'm not on screen & just talking, that's me more than likely scruffy as per the ILMers!.I second that ! You can't make too many of these videos. It's like watching ILM back in '77. All you need is a beard, long hair, and a flannel shirt and your there.

; ) Cheers,

Joe

Thank you so much Searun. I'm glad you are enjoying my videos & it's helping with your build.eagle1- great video again. The armor segment lines, notch location attention to detail, etc. wonderfully explained. Your build is in a class all its own.

I am much admiring your build, the different techniques you are using are just incredible!. I would say you are using 'hard' materials such as the ply & metal & mine is 'soft' materials of plastics & MDF.

All rod up to 3mm is solid styrene from Evergreen. The bigger sizes are hollow butyrate Plastruct items.Stu. Are you using solid rod or hollow pipe to do your piping? Both terms are used in this thread.

bwayne64

Master Member

Yeah, I'm about 3 months past due for a haircut. With my beard I'm looking like John Dykstra, ; ) If my Galactica was finished I would pose with her like the famous picture, LOL. Oh well I was a kid during the 70s so I'll just relive the decade. Cheers,Ha, thanks man!. When I'm not on screen & just talking, that's me more than likely scruffy as per the ILMers!.

Joe

bwayne64

Master Member

Stu, I know it's probably somewhere in the thread, but I couldn't find it. What thickness of styrene did you use for the mandibles. Also are the maintenance pits on top and bottom in line with each other. I know they're different on each side. But didn't know if they line up vertically. The blue prints from Vfx and Maruska don't show dimensions on the bottom mandibles. Thanks,

Joe

Joe

Hey Joe,Stu, I know it's probably somewhere in the thread, but I couldn't find it. What thickness of styrene did you use for the mandibles. Also are the maintenance pits on top and bottom in line with each other. I know they're different on each side. But didn't know if they line up vertically. The blue prints from Vfx and Maruska don't show dimensions on the bottom mandibles. Thanks,

Joe

I used 3mm styrene.

Through alot of working out i ascertained that that no pits were placed evenly from side to side or top & bottom. I had to work out each one individually with kit part placement & distancing between the kit parts to mandible edges & even measuring the nibbles/lengths of each styrene armor plate.

bwayne64

Master Member

Thanks man, I was going to use acrylic but styrene is so much easier to cut. I wasn't sure about the bottom pits. I'll do as you did and lay out the bottom with parts. That's if I have the kits to do it,Hey Joe,

I used 3mm styrene.

Through alot of working out i ascertained that that no pits were placed evenly from side to side or top & bottom. I had to work out each one individually with kit part placement & distancing between the kit parts to mandible edges & even measuring the nibbles/lengths of each styrene armor plate.

; ) Yeah don't even want to think about the nibbles and armor yet, yowzaas ! That gonna be a job. Oh well this is why we get the big bucks, oh wait, we're not getting paid, LOL. Except in the joy of having something that only a handful of people do. Cheers,

Joe

Hey guys!.

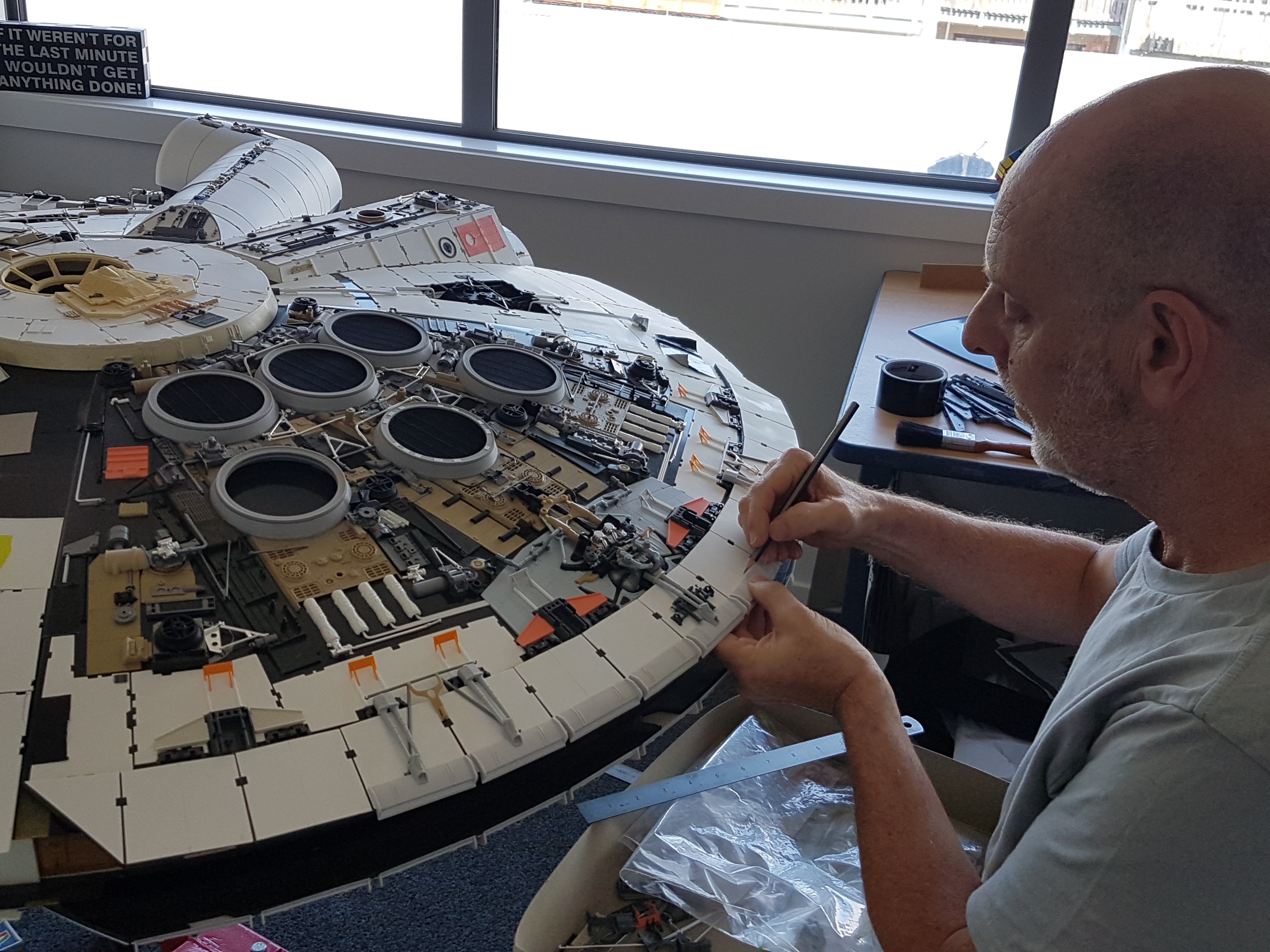

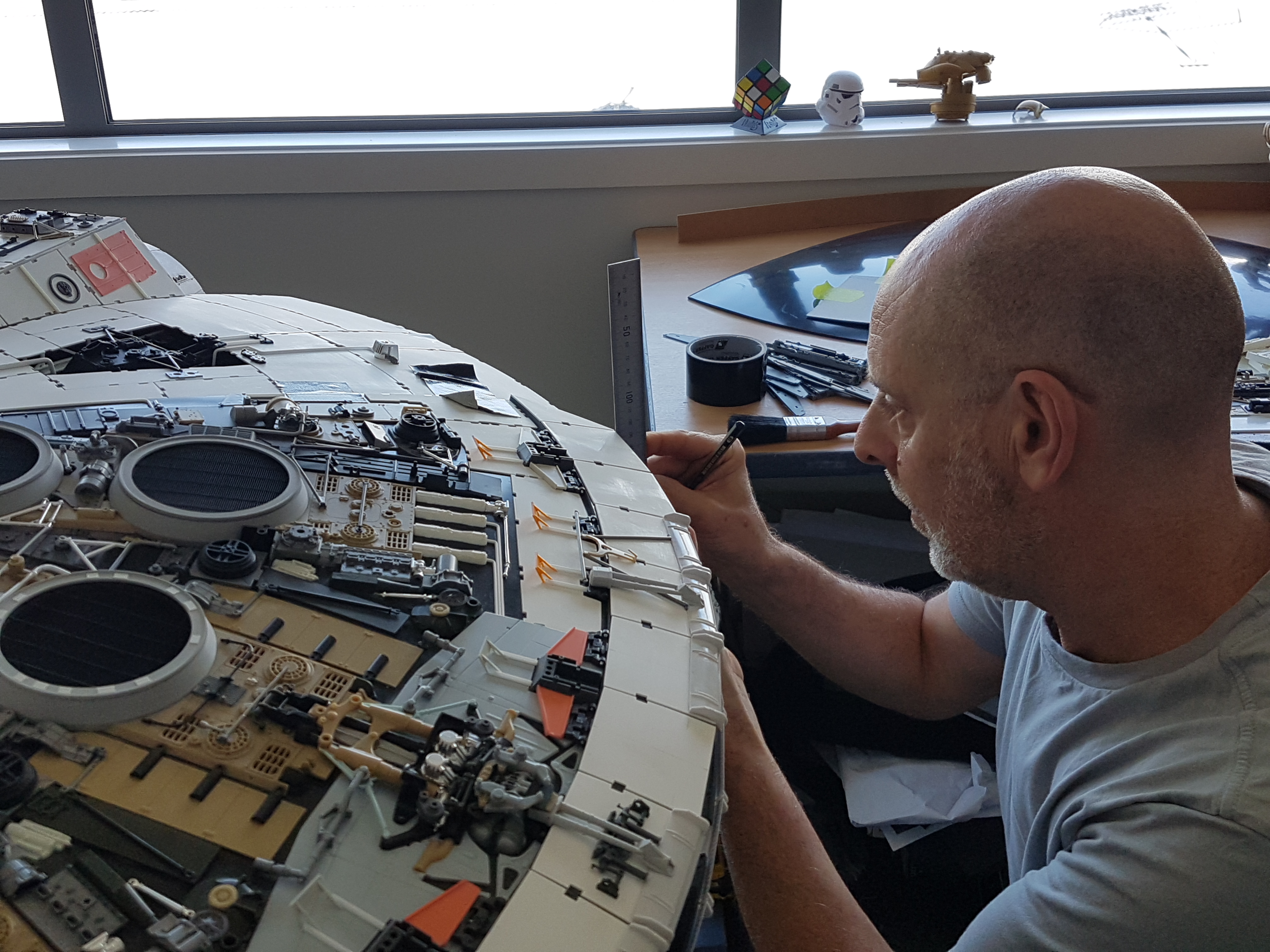

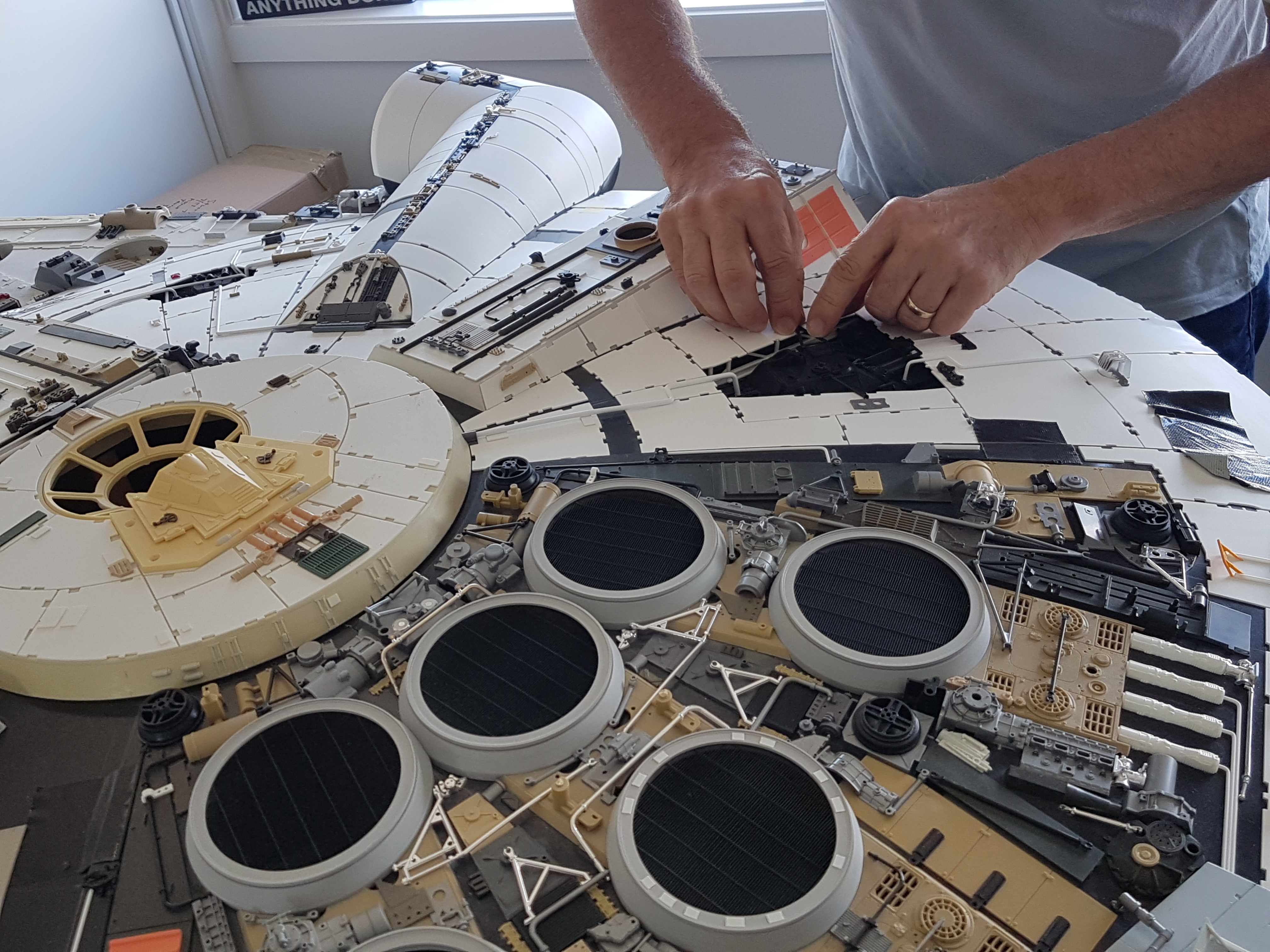

A few pics of me working around the Falcons rear end & what a complicated rear end she has!.

Nearly finished up the engine petal strips top & bottom. Gets repetitive here in that there are 26 styrene plates, 26 M8 plough blades & 26 struts to add. I'm finding going back to this area in intervals works best for me, while working on other others, keeps the interest levels up & not bogged down on one set area for long.

The dome sets i have had to reorganise with another fabricator for some of you, this has been a real, lets say 'challenge' to get right in how i envisioned them, but they will be delivered to all who ordered them.

Cheers

Stu

A few pics of me working around the Falcons rear end & what a complicated rear end she has!.

Nearly finished up the engine petal strips top & bottom. Gets repetitive here in that there are 26 styrene plates, 26 M8 plough blades & 26 struts to add. I'm finding going back to this area in intervals works best for me, while working on other others, keeps the interest levels up & not bogged down on one set area for long.

The dome sets i have had to reorganise with another fabricator for some of you, this has been a real, lets say 'challenge' to get right in how i envisioned them, but they will be delivered to all who ordered them.

Cheers

Stu

Beautiful shots.

You know if you need a break from building, you could just take some pics of all those pretty boxes.

You know if you need a break from building, you could just take some pics of all those pretty boxes.

Georgeousness and Georgeosity!!

Is that Katiusza on the floor meant to taunt us, or teach us? Either way, it's working...

Is that Katiusza on the floor meant to taunt us, or teach us? Either way, it's working...

Similar threads

- Replies

- 3

- Views

- 715

- Replies

- 11

- Views

- 995