-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interest Luke / Vader ANH shared stunt saber kit

Hello there,

first real progress on this project

I have cut all the tubes, then spent most of the days with my hands in water, wet sanding the tubes, 220, 400, 600. As usual, I'm not doing idealized props, so the tubes are clearly not perfect, I did them the same way they did for the movie, raw tube with all its flaws and scratches, sanded a bit, but you can still see a lot of weathering on the tubes. I hope that will be ok for people, those tubes were not lathed or anything, so they aren't perfect

I then cut the front angle on the first half of the tubes that I sanded. Couldn't do more than this today, my hands are completely wrinkled and sore from the first 30 tubes. will try my best to do the other half tomorrow

I also printed an accurate resin template that I can slide on the tubes to mark exactly the shape of the front emiter

Still busy with plenty of other things, but will try to move this forward more often now

cheers all

first real progress on this project

I have cut all the tubes, then spent most of the days with my hands in water, wet sanding the tubes, 220, 400, 600. As usual, I'm not doing idealized props, so the tubes are clearly not perfect, I did them the same way they did for the movie, raw tube with all its flaws and scratches, sanded a bit, but you can still see a lot of weathering on the tubes. I hope that will be ok for people, those tubes were not lathed or anything, so they aren't perfect

I then cut the front angle on the first half of the tubes that I sanded. Couldn't do more than this today, my hands are completely wrinkled and sore from the first 30 tubes. will try my best to do the other half tomorrow

I also printed an accurate resin template that I can slide on the tubes to mark exactly the shape of the front emiter

Still busy with plenty of other things, but will try to move this forward more often now

cheers all

Hello there!

some good progress made

all body tubes are cut, sanded and angled and waiting for the next steps:

cut cores:

drilled 9mm for rod clearance, then 13mm for moving part of the bearing clearance:

then faced clean and bored 22mm for the bearings:

and finaly, some good news with the motors! I have been waiting for those for one month and a half! no updates for 23 days on tracking, and they showed up today it was some of the worst packing ever and I still need to see if they work (I have been warned that those are fragile and often don't work), but at least they are here!

it was some of the worst packing ever and I still need to see if they work (I have been warned that those are fragile and often don't work), but at least they are here!

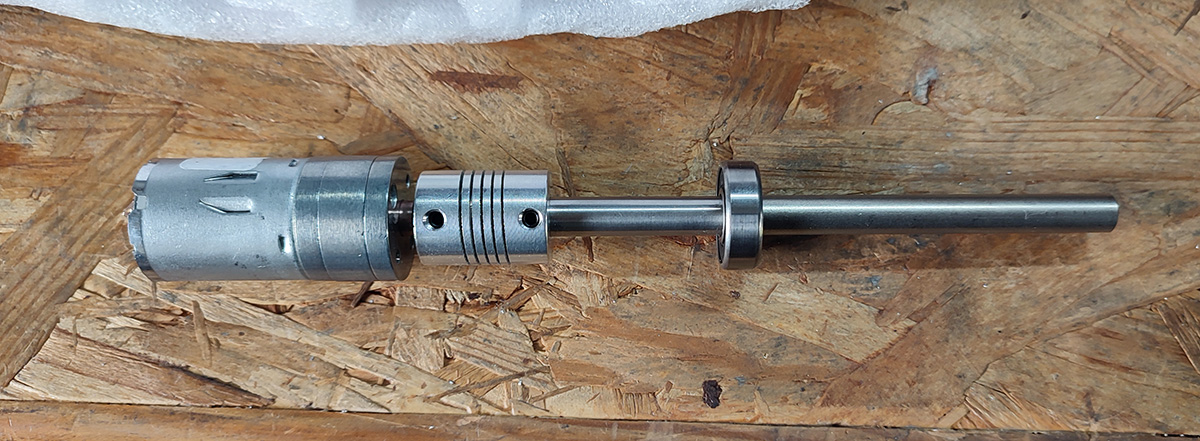

this is how the motor assembly will look:

there you go! still just starting on the run, but making good progress already I think

cheers all

some good progress made

all body tubes are cut, sanded and angled and waiting for the next steps:

cut cores:

drilled 9mm for rod clearance, then 13mm for moving part of the bearing clearance:

then faced clean and bored 22mm for the bearings:

and finaly, some good news with the motors! I have been waiting for those for one month and a half! no updates for 23 days on tracking, and they showed up today

this is how the motor assembly will look:

there you go! still just starting on the run, but making good progress already I think

cheers all

they are stupider than ever, look at themBeautiful work, but important question….

How’s the donkeys?!

daddy daddy, the door is closed, we ate grass all day and we are still starving!

I would also like mine motorised if possible

Incredible! I love these updatesthey are stupider than ever, look at them

daddy daddy, the door is closed, we ate grass all day and we are still starving!

View attachment 1809341

Folmer Buttons should be finished next week!!!

Folmer Red Button - Roman Props | Roman's Empire

View attachment 1810992

Outstanding!!

thank you so much RomanFolmer Buttons should be finished next week!!!

Folmer Red Button - Roman Props | Roman's Empire

View attachment 1810992

Folmer Buttons should be finished next week!!!

Folmer Red Button - Roman Props | Roman's Empire

View attachment 1810992

Hello there,

small but important update,

Knurling.

bane of my existence!

Knurling is hard to make on a relatively small lathe. There are also different type of knurling and knurling tools. Diamond knurling is actually simpler to make because it is made with a double wheel that each does one diagonal. You tighten the tool itself, don't really push with the lathe chariot.

Straight knurling is hell.

you have to push the tool into the material really hard to make the knurl appear little by little. The thing is, with my lathe, the material was usually stronger than the tightening of the lathe chariot and tool holder, so they started to turn more and more as i pushed on the material, never really managing to get into the material.

So, I added a first strong screw to hold the tool holder better and prevent him for rotating when pushing into the material, but then the perpendicular charriot started to turn on its axis as well and this one is harder to prevent.

I disassembled the whole system today to drill into it and add another screw that will only be there when doing knurling.

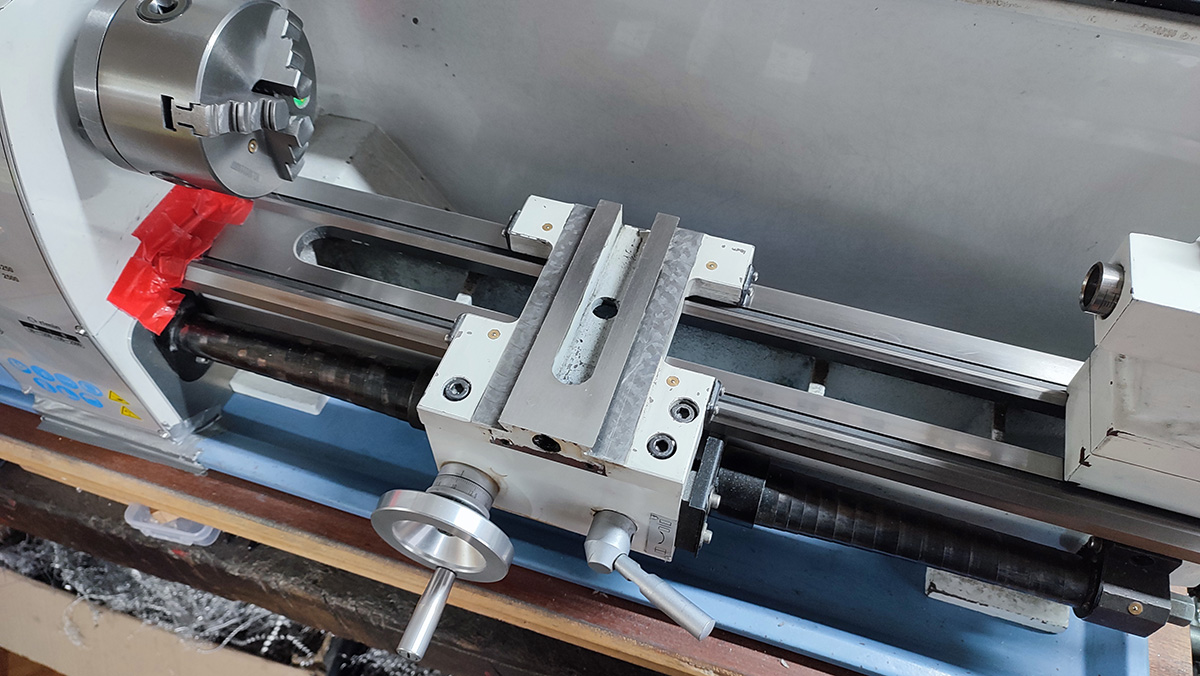

here is the lathe without any tool support anymore, good opportunity to cleanup everything as I never removed the big charriot before.

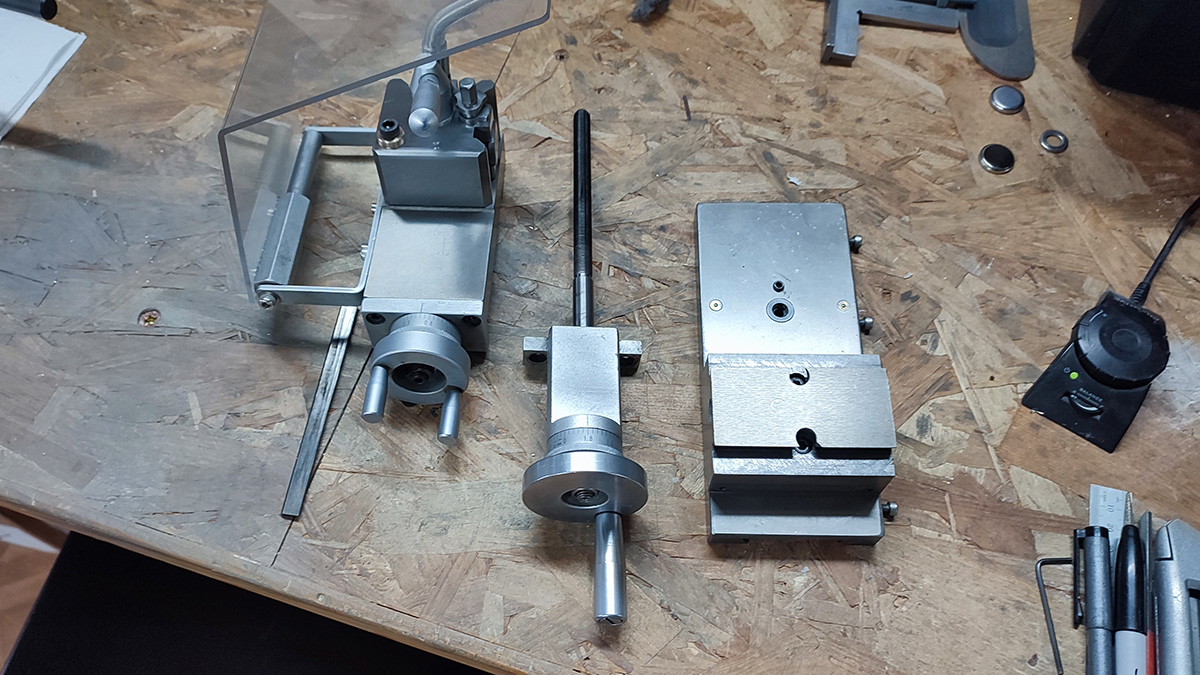

all the parts...

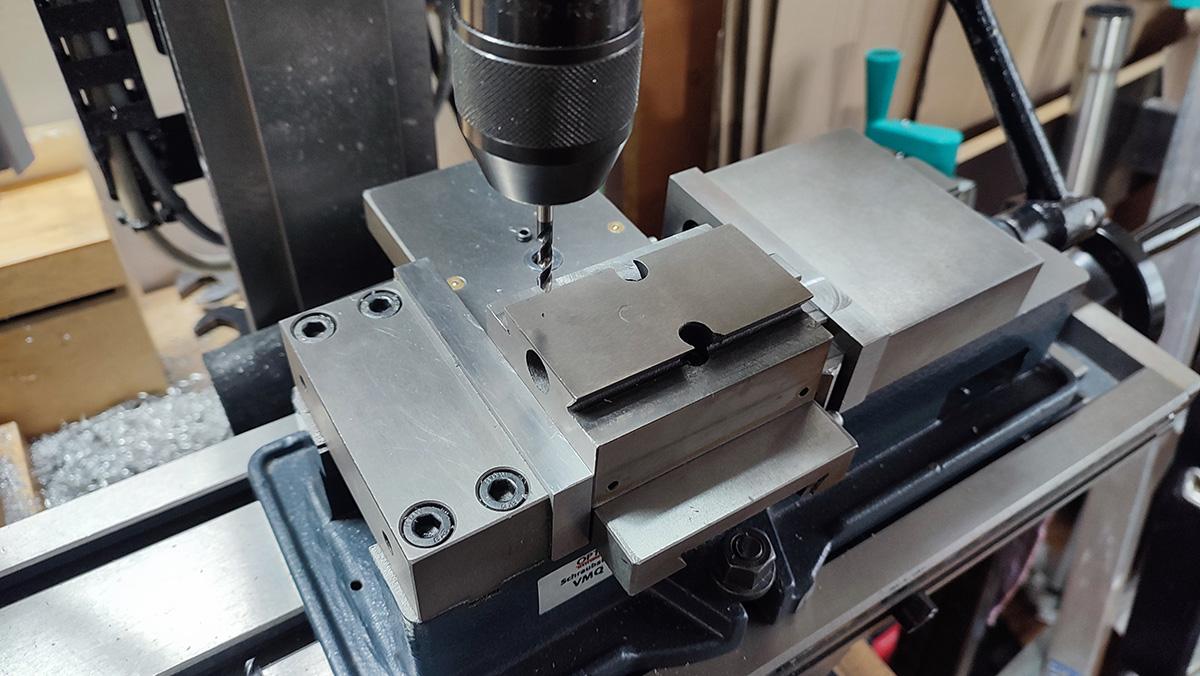

and now we want to drill a 6mm hole into 5cm deep of tool steel! yay!

luckily I have great drill bits now that will drill into really anything, so it's not that hard anymore. It was a lot harder the first time I had to adapt that tool holder to the lathe!

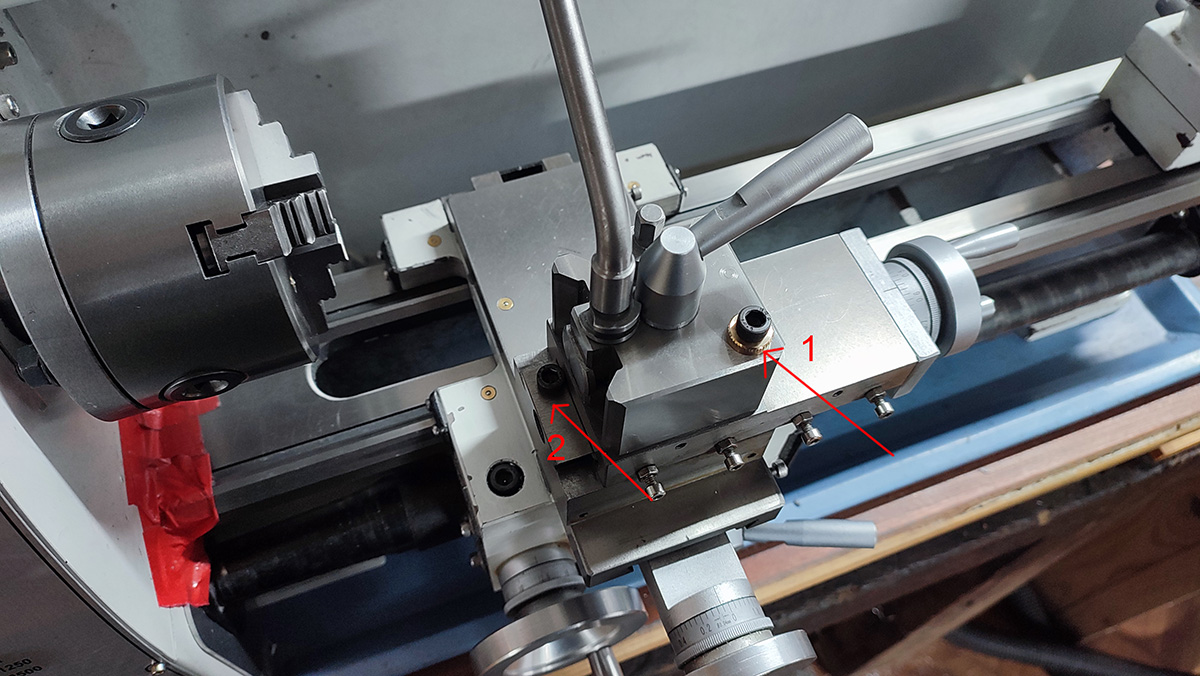

anyways, didn't take other photos of the process, but here is the lathe reassembled with the two additional 12.8 quality steel screws:

Screw #2 can obviously only be there when I do knurling and needs to be removed when using the chariot. screw #1 can be there most of the time and rigidifies the whole tool holder nicelly

#2 is doing a great job at keeping the charriot perpendicular now. However, with my last test, it seems the tool holder is still rotating a bit now even with screw #1! I have tightened everything a bit more tonight, i'll see if it works or if needs a 3rd screw!

in any case, mostly successful, this is the best straight knurling that came out of that lathe so far! knurls are well formed. I have still a bit that I would like to improve, but it has mostly to do with how to hold the part. But it looks like we will get nice knurled end caps for this run

cheers all!

small but important update,

Knurling.

bane of my existence!

Knurling is hard to make on a relatively small lathe. There are also different type of knurling and knurling tools. Diamond knurling is actually simpler to make because it is made with a double wheel that each does one diagonal. You tighten the tool itself, don't really push with the lathe chariot.

Straight knurling is hell.

you have to push the tool into the material really hard to make the knurl appear little by little. The thing is, with my lathe, the material was usually stronger than the tightening of the lathe chariot and tool holder, so they started to turn more and more as i pushed on the material, never really managing to get into the material.

So, I added a first strong screw to hold the tool holder better and prevent him for rotating when pushing into the material, but then the perpendicular charriot started to turn on its axis as well and this one is harder to prevent.

I disassembled the whole system today to drill into it and add another screw that will only be there when doing knurling.

here is the lathe without any tool support anymore, good opportunity to cleanup everything as I never removed the big charriot before.

all the parts...

and now we want to drill a 6mm hole into 5cm deep of tool steel! yay!

luckily I have great drill bits now that will drill into really anything, so it's not that hard anymore. It was a lot harder the first time I had to adapt that tool holder to the lathe!

anyways, didn't take other photos of the process, but here is the lathe reassembled with the two additional 12.8 quality steel screws:

Screw #2 can obviously only be there when I do knurling and needs to be removed when using the chariot. screw #1 can be there most of the time and rigidifies the whole tool holder nicelly

#2 is doing a great job at keeping the charriot perpendicular now. However, with my last test, it seems the tool holder is still rotating a bit now even with screw #1! I have tightened everything a bit more tonight, i'll see if it works or if needs a 3rd screw!

in any case, mostly successful, this is the best straight knurling that came out of that lathe so far! knurls are well formed. I have still a bit that I would like to improve, but it has mostly to do with how to hold the part. But it looks like we will get nice knurled end caps for this run

cheers all!

I wish I could have been a part of this run. I just couldn't commit financially.

don't worry too much about it,I wish I could have been a part of this run. I just couldn't commit financially.

47 sabers on the interest list, 60 being made, several price options. A few weeks left before public release on the website.

cheers

SethSolo510

New Member

don't worry too much about it,

47 sabers on the interest list, 60 being made, several price options. A few weeks left before public release on the website.

cheers

Attachments

Similar threads

- Sale

- Replies

- 8

- Views

- 622

- Sale

- Replies

- 14

- Views

- 1,250

- Replies

- 4

- Views

- 931

- Replies

- 7

- Views

- 1,477