Vidar 710

Well-Known Member

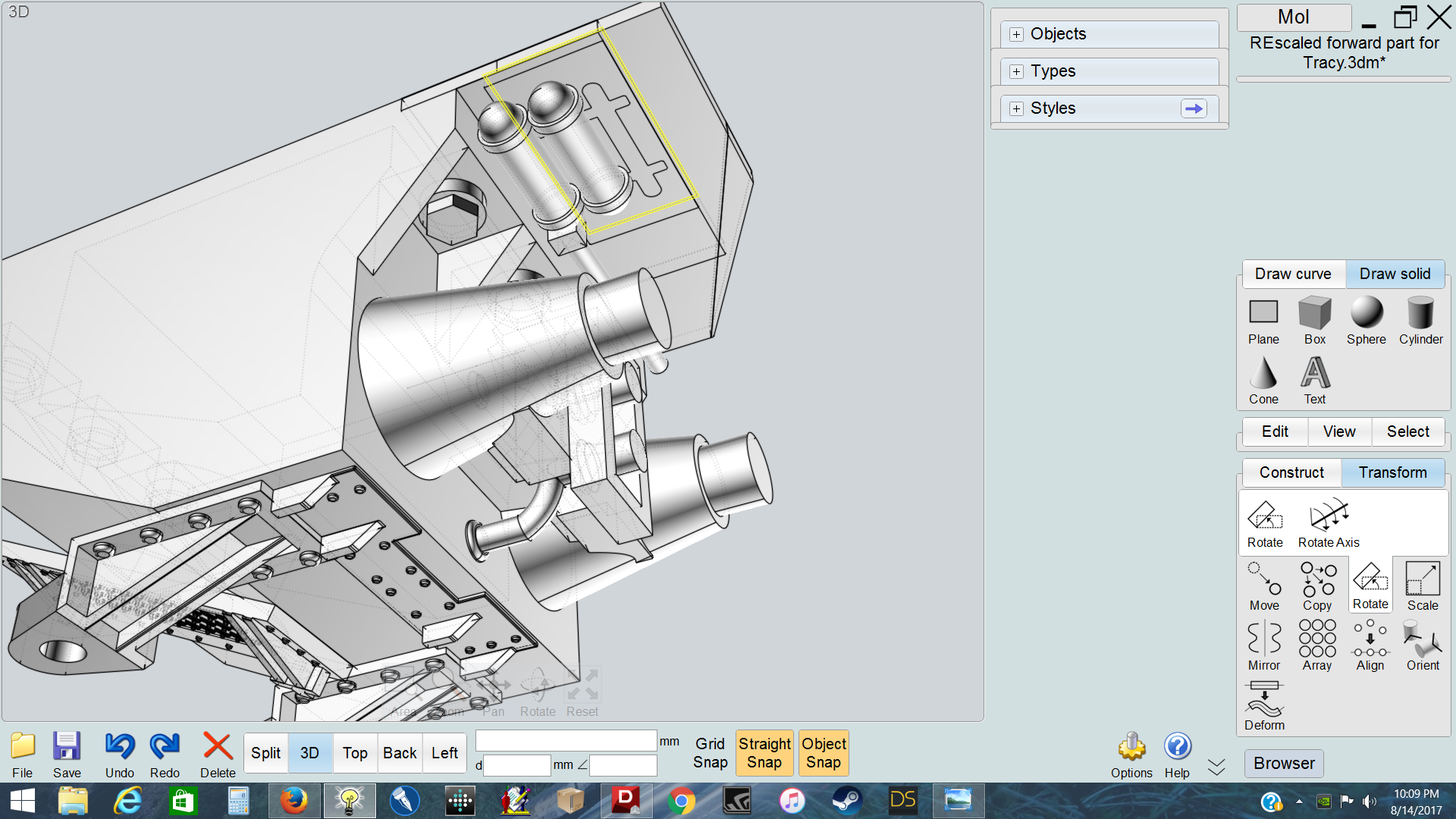

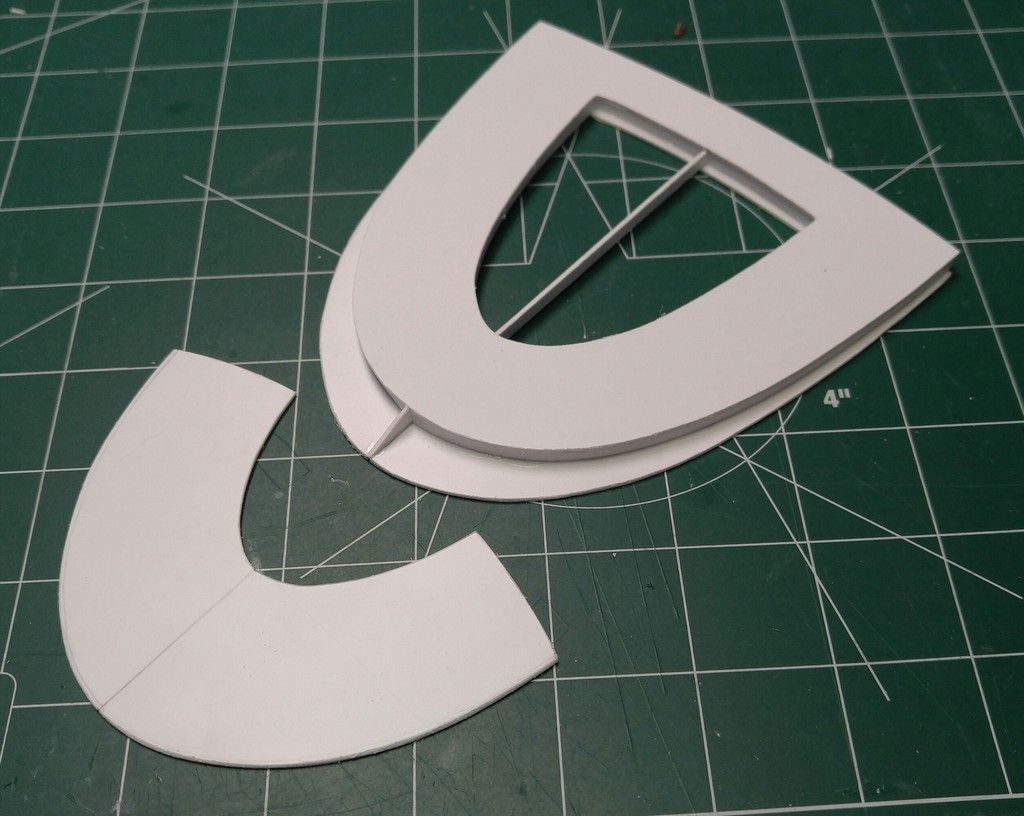

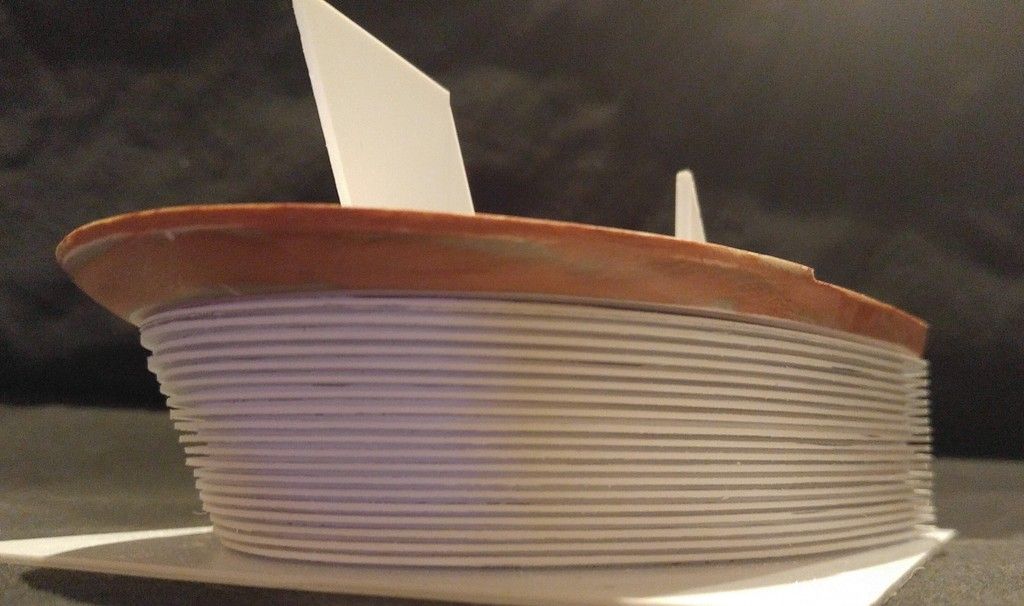

Dorsal assembly in-progress images.

The entire assembly is scratch-built. However, the inserts in the front of the dorsal will be 3D printed.

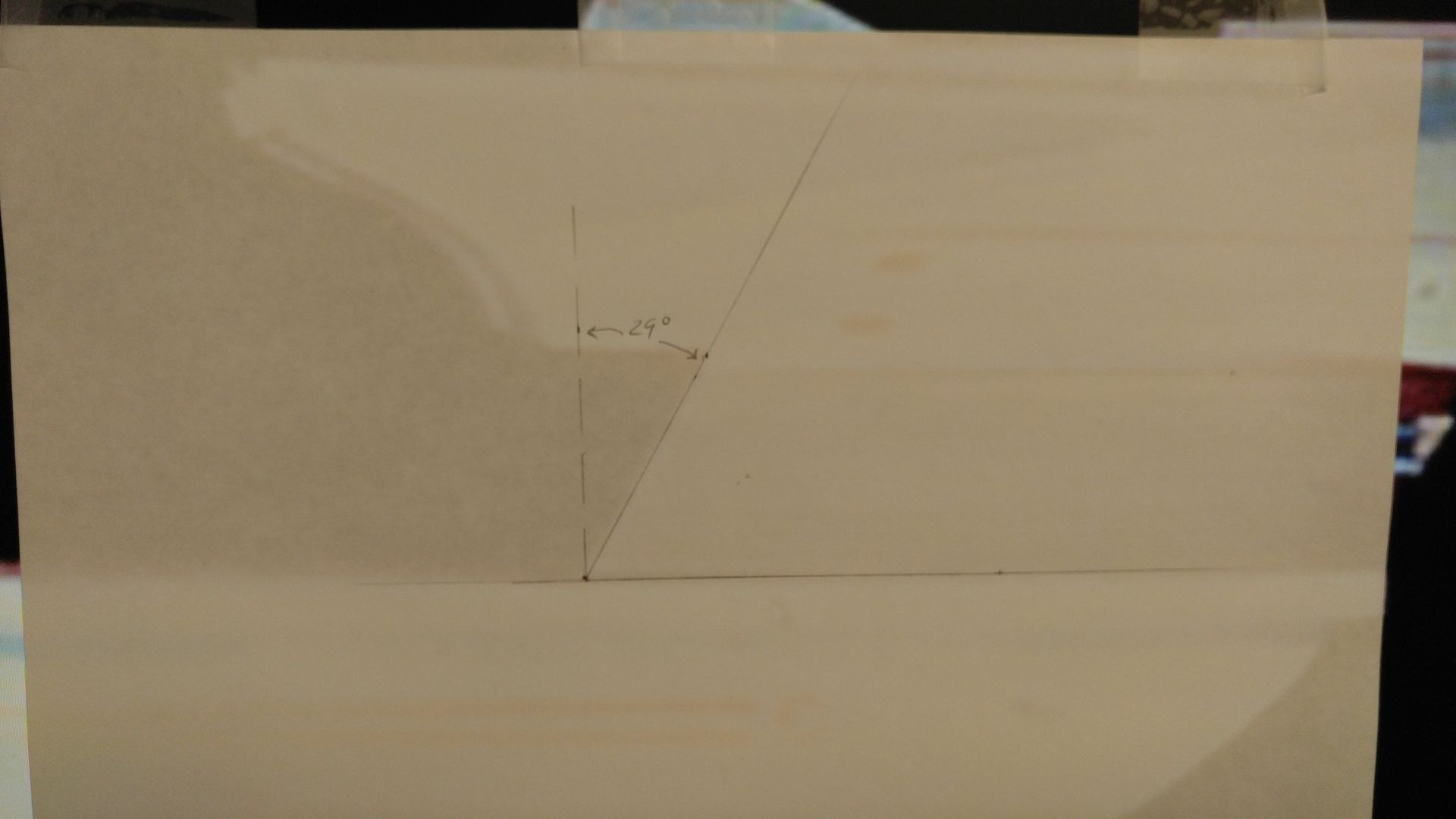

Cutting the styrene by hand.

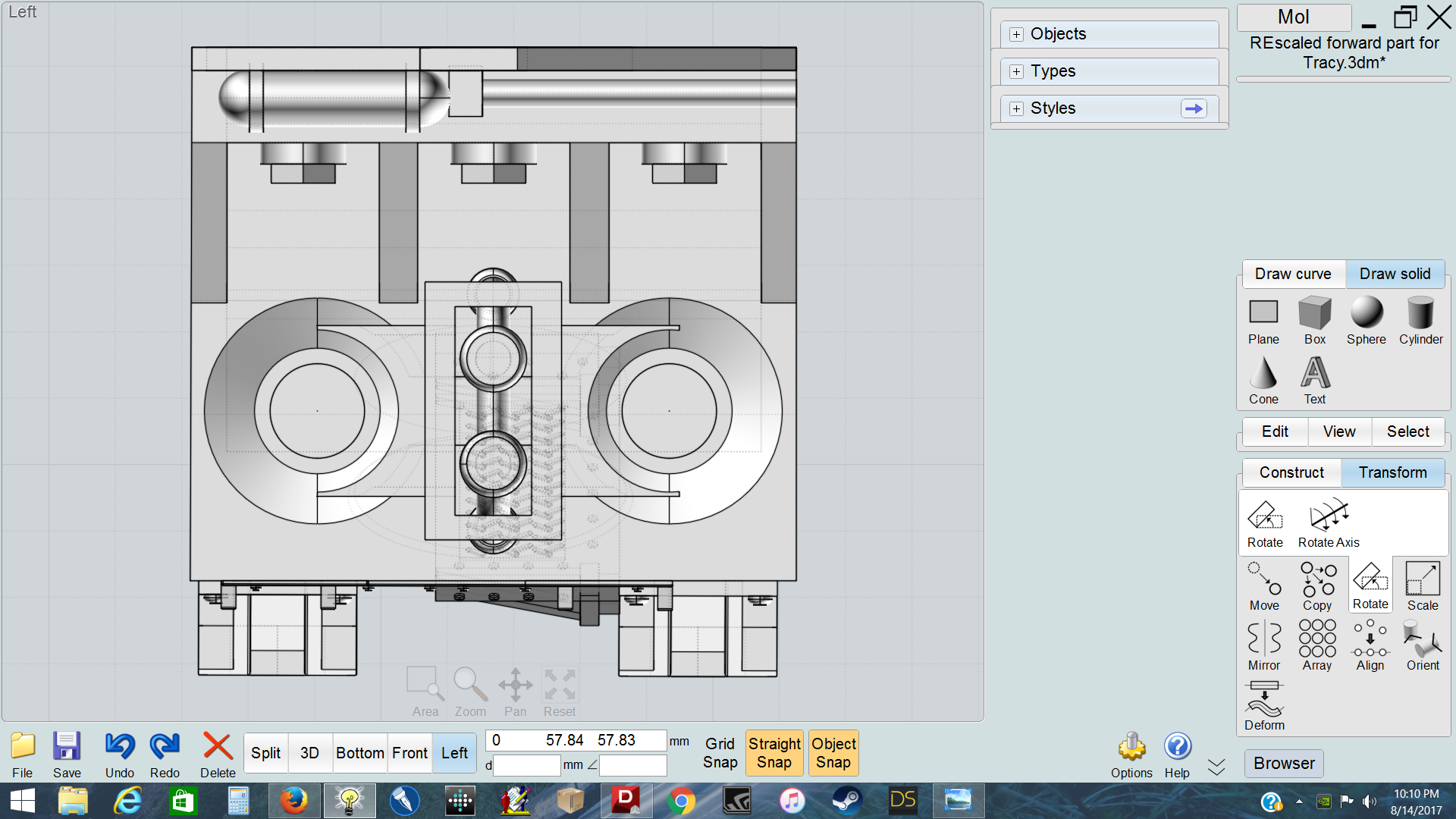

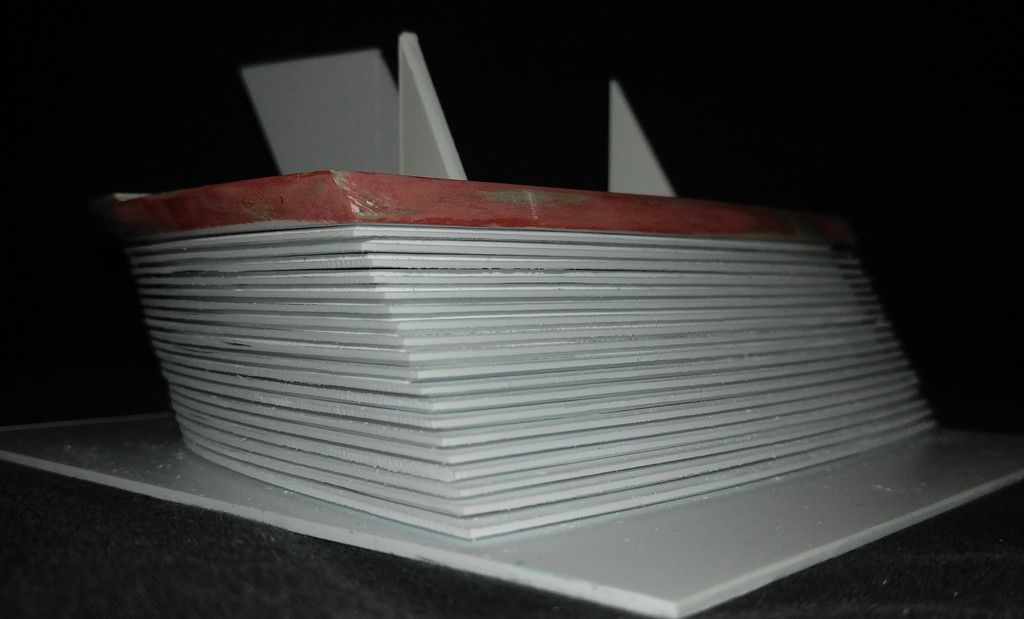

41 plates were cut. More than half that didn't quite make the grade were relegated to being trimmed down to be the spacer plates.

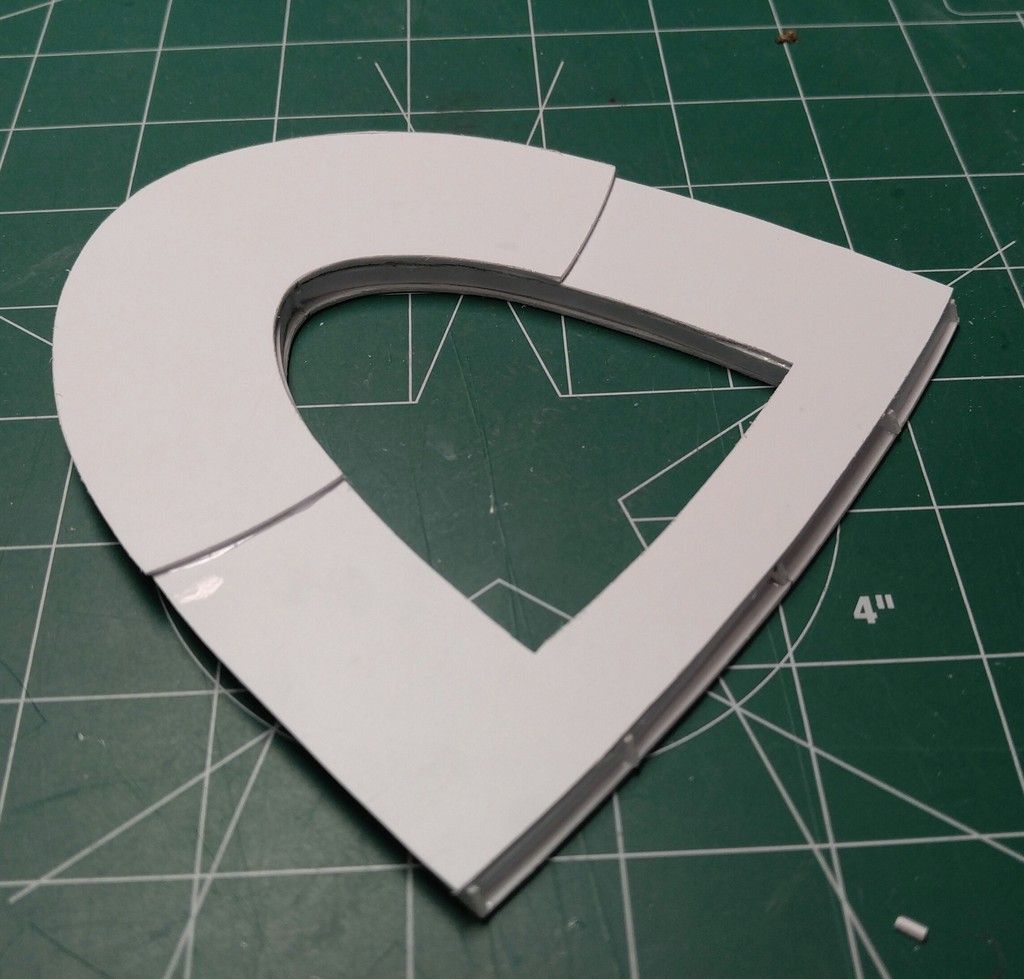

The Large plates and Spacer plates were clamped together for sanding to unify their shape.

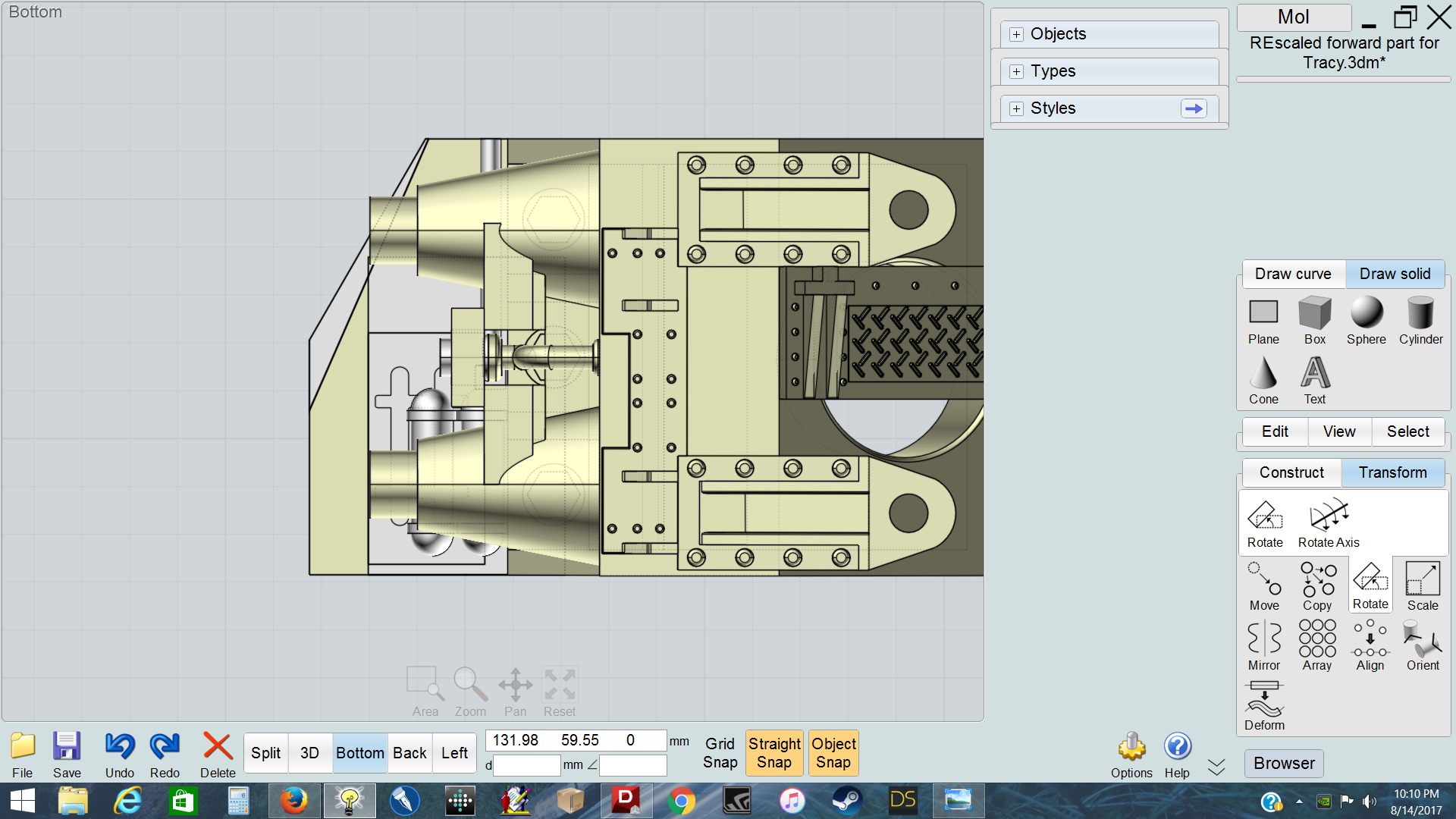

The Upper Adapter that attaches the dorsal to the primary hull is framed in styrene...

... then shaped with Apoxie Sculpt.

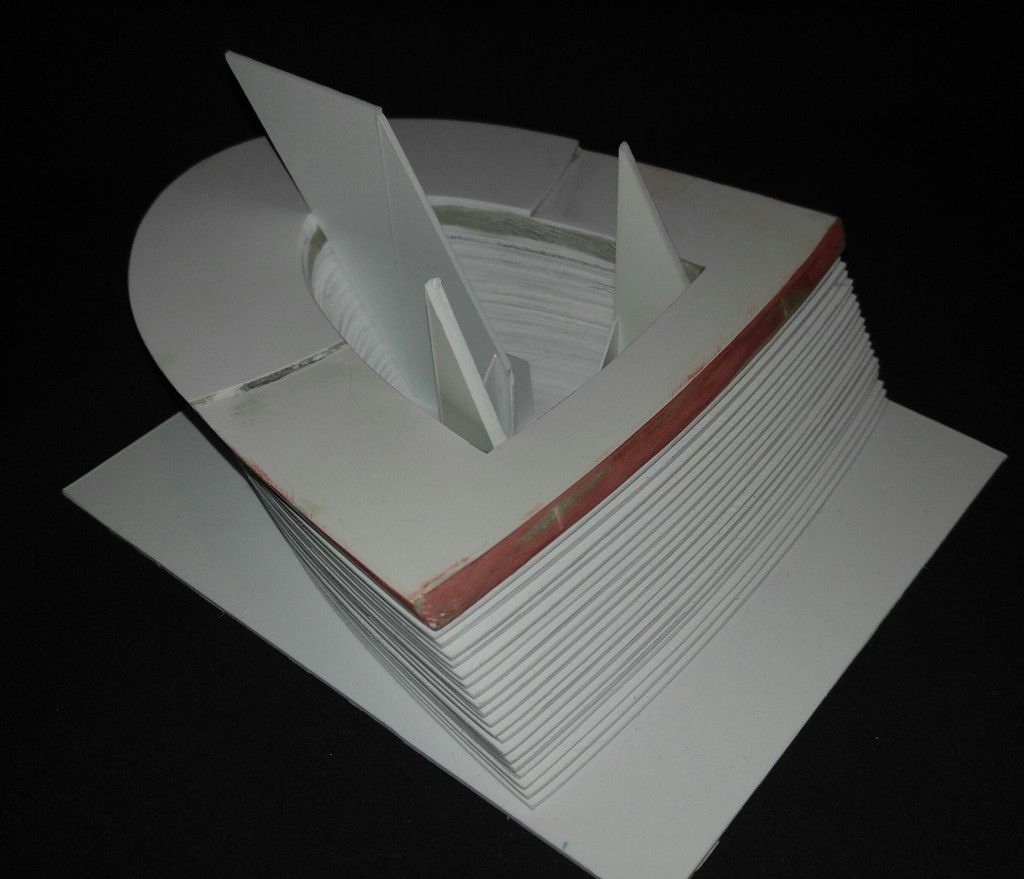

Here, the ruffed out parts are stacked unglued at this point to check for alignment.

Clean-up of the individual plates and the cutting of the two forward ports is the next step.

Thanx for lookin'!

Tracy

The entire assembly is scratch-built. However, the inserts in the front of the dorsal will be 3D printed.

Cutting the styrene by hand.

41 plates were cut. More than half that didn't quite make the grade were relegated to being trimmed down to be the spacer plates.

The Large plates and Spacer plates were clamped together for sanding to unify their shape.

The Upper Adapter that attaches the dorsal to the primary hull is framed in styrene...

... then shaped with Apoxie Sculpt.

Here, the ruffed out parts are stacked unglued at this point to check for alignment.

Clean-up of the individual plates and the cutting of the two forward ports is the next step.

Thanx for lookin'!

Tracy