-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Limited Run Cloud city blaster - Relby K23 - aluminium conversion kits! interest for a possible new run?

Order placed—thank you!

I've ordered mine. Thanks a bunch for taking on this project.

I have this secret plan to drill a little hole in the back of a resin V8 part. The trigger is held in place by a hinge pin and the rod that reaches into the canister and pulls the piston. Without it, the trigger can flop around. I guess you can glue the trigger itself in place, now that I think about it. I was just going to affix the rod inside the cap...

this reply went haywire, and I need to go back to my drawings lol

this reply went haywire, and I need to go back to my drawings lol

hey there,

small update after the rush of this week end!

I managed to finish the last gears I needed to finish, I actually put the kits for sale before all the gears were done because I had enough to cover the first orders I was anticipating and didn't want to be to delayed

here is the traditional end of run photo, it has almost all the parts even though a few have been already sent out:

Now, if you are wondering what those boxes are when you receive you kit, in my always eco friendly way of handling things, I'm doing my boxes myself for this run and am using reused but basically new boxes from the Winery next door, my wife has been working there for the summer and she saved a lot of boxes that they were just trowing away after removing the bottles from them.

they are great because the cardboard is quite thin but very dense and strong, they are perfect to ship small objects; especially with that 3cm thickness limit for a cheaper shipping cost

lastly, here is how the items are packed together so you get an idea when opening the things and don't loose the small parts.

The gears and barrel are dry fit together in the proper position, if you keep it that way, you just have to slide them over the cut barrel. I taped the sights to them to avoid loosing them as they are super tiny.

The washers are packed together with the V8 cone when you ordered this variation. If you haven't ordered the V8 cone, the washer is packed by itself, be carefull not to misplace it.

All orders from this week end are packed, just need to print the labels, they will all ship monday morning, you'll receive your tracking number by e-mail, if you don't receive it, please check your spams before contacting me.

I hope that the rest of the orders will follow soon, so far I have only received 10 orders out of the 21 people from the list. As I explained, I'm happy to cover all expenses in advance and to not take pre-payment, and I don't want to change that in the future. However, things are a bit tense for me right now as I have been producing a lot at the same time and this is the first complete project in several months that I'm able to release. I need to order my new machine and funds are tight right now, thank you for your help!

I hope you'll like the kits and I hope to see you again for my next cool project, the Barbican saber and Square shroud stunt saber!

cheers

small update after the rush of this week end!

I managed to finish the last gears I needed to finish, I actually put the kits for sale before all the gears were done because I had enough to cover the first orders I was anticipating and didn't want to be to delayed

here is the traditional end of run photo, it has almost all the parts even though a few have been already sent out:

Now, if you are wondering what those boxes are when you receive you kit, in my always eco friendly way of handling things, I'm doing my boxes myself for this run and am using reused but basically new boxes from the Winery next door, my wife has been working there for the summer and she saved a lot of boxes that they were just trowing away after removing the bottles from them.

they are great because the cardboard is quite thin but very dense and strong, they are perfect to ship small objects; especially with that 3cm thickness limit for a cheaper shipping cost

lastly, here is how the items are packed together so you get an idea when opening the things and don't loose the small parts.

The gears and barrel are dry fit together in the proper position, if you keep it that way, you just have to slide them over the cut barrel. I taped the sights to them to avoid loosing them as they are super tiny.

The washers are packed together with the V8 cone when you ordered this variation. If you haven't ordered the V8 cone, the washer is packed by itself, be carefull not to misplace it.

All orders from this week end are packed, just need to print the labels, they will all ship monday morning, you'll receive your tracking number by e-mail, if you don't receive it, please check your spams before contacting me.

I hope that the rest of the orders will follow soon, so far I have only received 10 orders out of the 21 people from the list. As I explained, I'm happy to cover all expenses in advance and to not take pre-payment, and I don't want to change that in the future. However, things are a bit tense for me right now as I have been producing a lot at the same time and this is the first complete project in several months that I'm able to release. I need to order my new machine and funds are tight right now, thank you for your help!

I hope you'll like the kits and I hope to see you again for my next cool project, the Barbican saber and Square shroud stunt saber!

cheers

Ordered my kits! Thanks again eethan! Really do appreciate your hard work on this.

I have this secret plan to drill a little hole in the back of a resin V8 part. The trigger is held in place by a hinge pin and the rod that reaches into the canister and pulls the piston. Without it, the trigger can flop around. I guess you can glue the trigger itself in place, now that I think about it. I was just going to affix the rod inside the cap...

this reply went haywire, and I need to go back to my drawings lol

That´s basically what I did with my last build(s)

Extending the trigger rod into the V8 cone, adding a small spring and a nut and voilá..trigger still works

I have to admit I don’t know a ton about the greeblies on this blaster.

Maybe I missed it, somewhere in this thread, but can someone list / map the greeblies needed to complete a full build?

Maybe I missed it, somewhere in this thread, but can someone list / map the greeblies needed to complete a full build?

I think the best will be a handheld metal saw. the most important part is to be a bit flush in the back. If you are a bit too short in the front, it's not a big deal at all!What would be the easiest way to cut the blue barrel tube for someone without much in the way of tools and equipment? I do have a Dremel, but that’s it. Would a Dremel cutting bit work? Thanks!

possibly, if you want to clean up your work a bit, a simple flat metal file.

cheers

good question! I don't think that ALL the greeblies are identified yet on that blaster, if I'm not mistaken.I have to admit I don’t know a ton about the greeblies on this blaster.

Maybe I missed it, somewhere in this thread, but can someone list / map the greeblies needed to complete a full build?

If you need casts, Ryan Clinton Pedro and thd9791 are offering almost all the parts.

If you need original parts, I hope that someone a bit better versed that me can give you an actual list of parts. if not, all the info is pretty much found in this thread:

Bespin Guard Blaster Relby K-23 Greeblies, research, etc.

Hi folks, There is one public shot of this gun with some actual greeblies showing, not a cast of the gun with the greeblies included. I dont have a good res shot but, its this one from google Anyway - it got me thinking that the gears might be found parts, though the muzzle might not be...

cheers

A dremel reinforced cutting disc will work. Here’s how I would do it (2 ways)What would be the easiest way to cut the blue barrel tube for someone without much in the way of tools and equipment? I do have a Dremel, but that’s it. Would a Dremel cutting bit work? Thanks!

1) use a new dremel reinforced disc, so you have the biggest diameter or clearance to cut. Considering the size of the barrel and how far you can sink the dremel and stay straight (not much) I would do this. Wrap tape around the barrel so you have a straight line. Cut from one side, rotate the gun, cut again, rotate, cut, etc and spiral around. Hopefully you can breach the wall.

2) either as a “finish” to #1 or start with this. Go to a hardware store and grab a new hacksaw. Make your tape line, and do the same thing. Cut a little, rotate, cut, etc.

Both of these will leave a smooth surface if you sink through confidently but moderately slow. The tape line and the multiple cuts leave you less room to screw up. Many times if I cut right through a tube or something I end up at an angle somehow lol

Also on the parts, there are two greeblies still unidentified. The plate with 4 dots and that rectangular thing that is chopped up and used a few times. Oh and the stirring stick.

I have molds of the real f-4E triangle, and the calculator button. Not sure if my motor coil plate mold is still good I’ll have to check.

I used to have a mold of the back part and it ripped. I’m making a new one and I can make extras

I have molds of the real f-4E triangle, and the calculator button. Not sure if my motor coil plate mold is still good I’ll have to check.

I used to have a mold of the back part and it ripped. I’m making a new one and I can make extras

Hello guys,

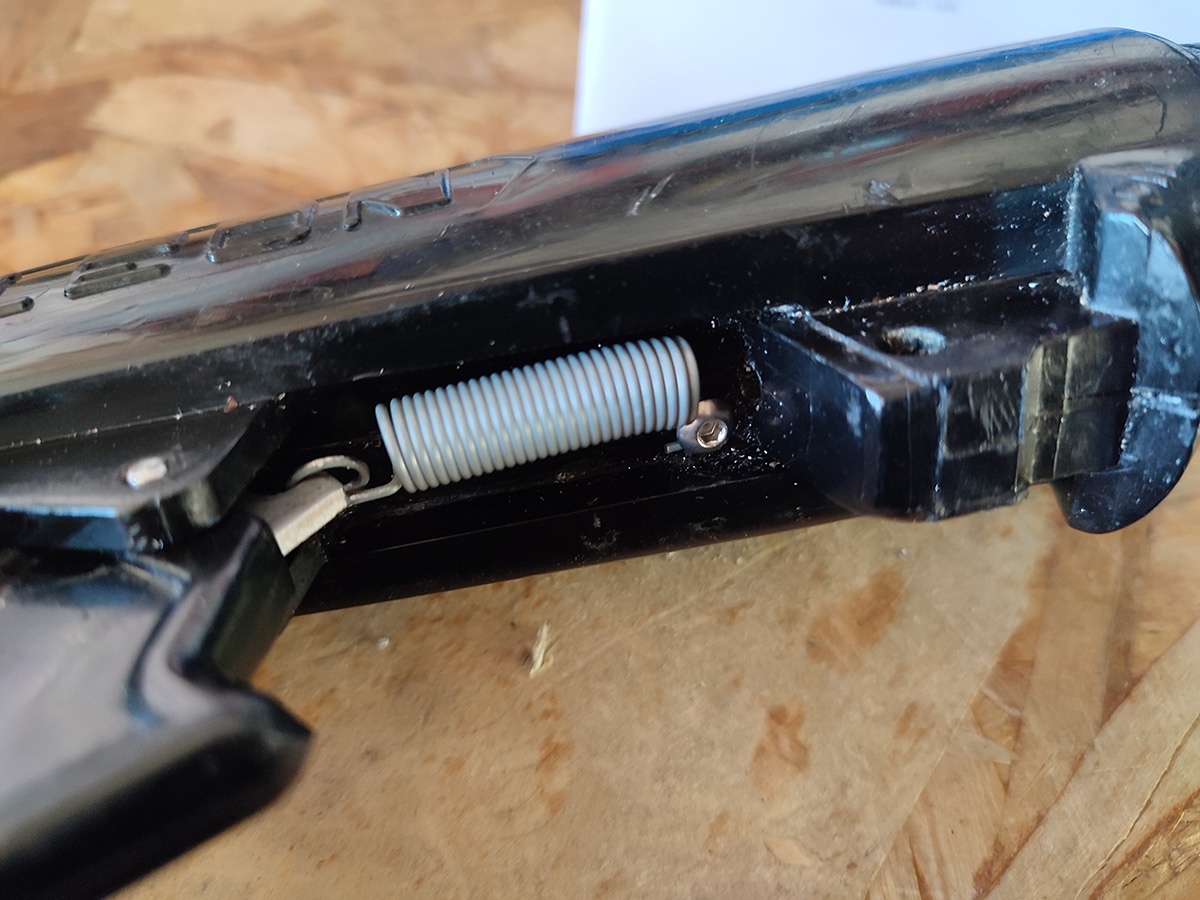

I saw that there was some discution about the trigger mechanism, so I tried my own as well to share and give you guys some options. There are countless options for this, there is room inside, there is a hook on the trigger that is very practical to use, the trigger will stop on both direction against the plastic of the pistol when re-assembled, so any good spring will give a nice feeling, what I did is pretty simple and I'm very happy with the result, it really "clicks" when you press the trigger

I just used a rather stiff spring that I attached to the trigger hook on one side, and I put a screw into the plastic and aluminium tube that goes inside and wrapped the other end of the spring to it :

and a short video of it working:

Unrelated, but I still haven't heard from a few people that are on the list, lmakeltraln MarcoCazares bobasfett dkraude . Please at least send me a PM if you changed your mind or plan to buy later on.

thank you

I saw that there was some discution about the trigger mechanism, so I tried my own as well to share and give you guys some options. There are countless options for this, there is room inside, there is a hook on the trigger that is very practical to use, the trigger will stop on both direction against the plastic of the pistol when re-assembled, so any good spring will give a nice feeling, what I did is pretty simple and I'm very happy with the result, it really "clicks" when you press the trigger

I just used a rather stiff spring that I attached to the trigger hook on one side, and I put a screw into the plastic and aluminium tube that goes inside and wrapped the other end of the spring to it :

and a short video of it working:

Unrelated, but I still haven't heard from a few people that are on the list, lmakeltraln MarcoCazares bobasfett dkraude . Please at least send me a PM if you changed your mind or plan to buy later on.

thank you

Similar threads

- Replies

- 16

- Views

- 1,424

Limited Run

Leia and Chewie ANH brass handcuffs

- Replies

- 167

- Views

- 13,719

- Replies

- 210

- Views

- 23,998

Done / Completed

The Expanse - MCRN pistol - machined aluminium conversion kit

- Replies

- 103

- Views

- 8,869