You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Y-Wing "Green Leader" Project - NOW OPEN SOURCE!

- Thread starter DaveG

- Start date

Vacformedhero

Sr Member

Wow Dave this is a masterclass in modern material use , and why 3D printers are a very useful tool in the right hands , very like the master Buck used to make aluminium hand made car bodies , beautiful work.

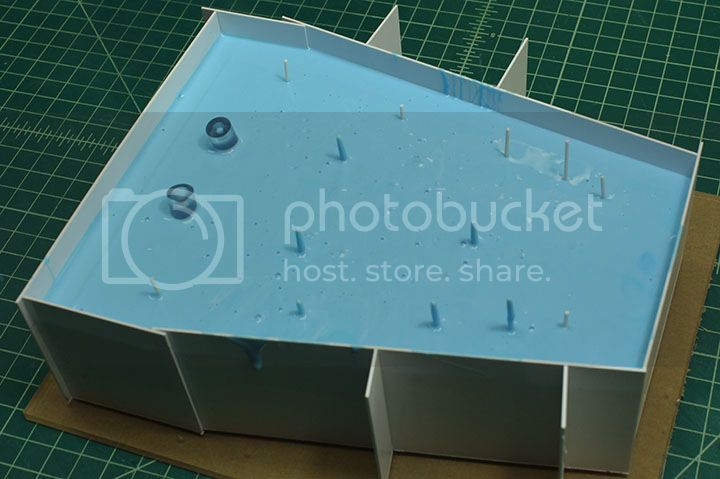

Thanks guys! One of the great things about using 3D modeling as part of the modelmaking process is not only the 3D printed parts it allows you to create but also jigs and fixtures to aid in the modelmaking process. In this case, sections cut through the model geometry were used to create the laser cutting files for the disposable acrylic eggcrate supports. Not absolutely necessary for making the molds but a great aid.

How will you make the pour and vent holes Dave? Cut into the rubber after the molds are done?

How will you make the pour and vent holes Dave? Cut into the rubber after the molds are done?

I'm add some pour and vent sprues before I pour the second halves. Then if I need more I can cut them into the mold. The rubber i'm useing is fairly hard so i can actually drill holes in to for vents if needed. I'm hoping to let the resin gravity feed but if necessary I'll use a big syringe and inject it prior to putting the mold in the pressure tank.

steve48442

Well-Known Member

beautiful work

I found this link as I was trolling the internet today that RPF member maruska posted a while back for 3D files of Sealab parts. Most are used on the X-Wing but there are some Y-wing parts also. I can't speak to their accuracy, but figured some would be interested.

https://grabcad.com/library/aurora-sealab-iii-studio-scale-kit-parts-1

https://grabcad.com/library/aurora-sealab-iii-studio-scale-kit-parts-1

Galactican

Sr Member

This thread is pure awesomeness!

@DaveG : Dave, I love your explanations about the "good ol' days". Thank you so much for taking the time for them. I'm sure if I had been at the shop back then I would never have left.

I have a question: I have seen how slowly the camera was moving around the models. How were you able to keep the motion blur intact in the final shot?

@DaveG : Dave, I love your explanations about the "good ol' days". Thank you so much for taking the time for them. I'm sure if I had been at the shop back then I would never have left.

I have a question: I have seen how slowly the camera was moving around the models. How were you able to keep the motion blur intact in the final shot?

It was fun but it was also an a times hard grueling job. There were lots of 12 hour a day seven day weeks. Going home was always nice!

The motion control camera movers were basically very precise stepper motor controlled robots built using precision mechanical slides and pivots. As long as the rig was built well and functioning correctly the camera would move very smoothly and at a slow consistent speed. Motion blur looks fine when shot that way.

The motion control camera movers were basically very precise stepper motor controlled robots built using precision mechanical slides and pivots. As long as the rig was built well and functioning correctly the camera would move very smoothly and at a slow consistent speed. Motion blur looks fine when shot that way.

Last edited:

Galactican

Sr Member

Ah, now I see! I forgot that the cams were moving during exposure..! Thanks for the info!

Back in the shop!

I've been in Orlando for the past week for work so have not been able to work on the fuselage molds. Now I'm back in the shop and got the second halves of the molds prepped and poured.

I glued some shot lengths of acrylic and styrene rod to the pattern to mold pour and vent channels in the second (top) halves of the molds. Casting soon!

I've been in Orlando for the past week for work so have not been able to work on the fuselage molds. Now I'm back in the shop and got the second halves of the molds prepped and poured.

I glued some shot lengths of acrylic and styrene rod to the pattern to mold pour and vent channels in the second (top) halves of the molds. Casting soon!

Last edited:

Hammer3246

Sr Member

Awesome, now ship it to me please. [emoji4]First casting out of the mold. Came out really nice. My original thought was that I would have to inject the resin but the pour sprue and vent gates worked fine for a gravity pour, no bubbles!

[url]http://i1053.photobucket.com/albums/s480/GoldbergArts/Y-Wing%20Build/IMG_0462_zpsbh7o5neb.jpg[/URL]

[url]http://i1053.photobucket.com/albums/s480/GoldbergArts/Y-Wing%20Build/IMG_0465_zpsslettkcm.jpg[/URL]

[url]http://i1053.photobucket.com/albums/s480/GoldbergArts/Y-Wing%20Build/IMG_0466_zpsrhpiacwj.jpg[/URL]

[url]http://i1053.photobucket.com/albums/s480/GoldbergArts/Y-Wing%20Build/IMG_0463_zpsffanibqf.jpg[/URL]

This is coming from my phone, expect errors.

Similar threads

- Sale

- Replies

- 8

- Views

- 902

- Replies

- 2

- Views

- 416