I've just started an interest thread for a run of the non-3D printed armature parts; Tee Plate, main spar and wing spar.

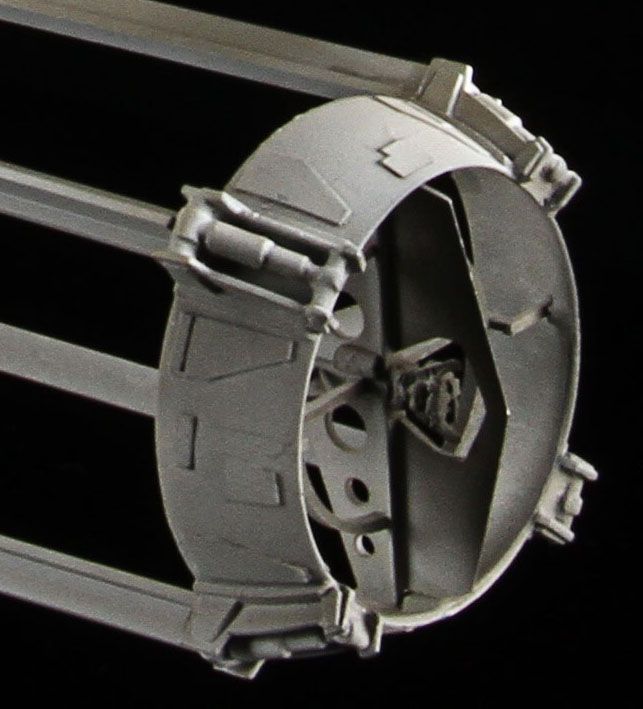

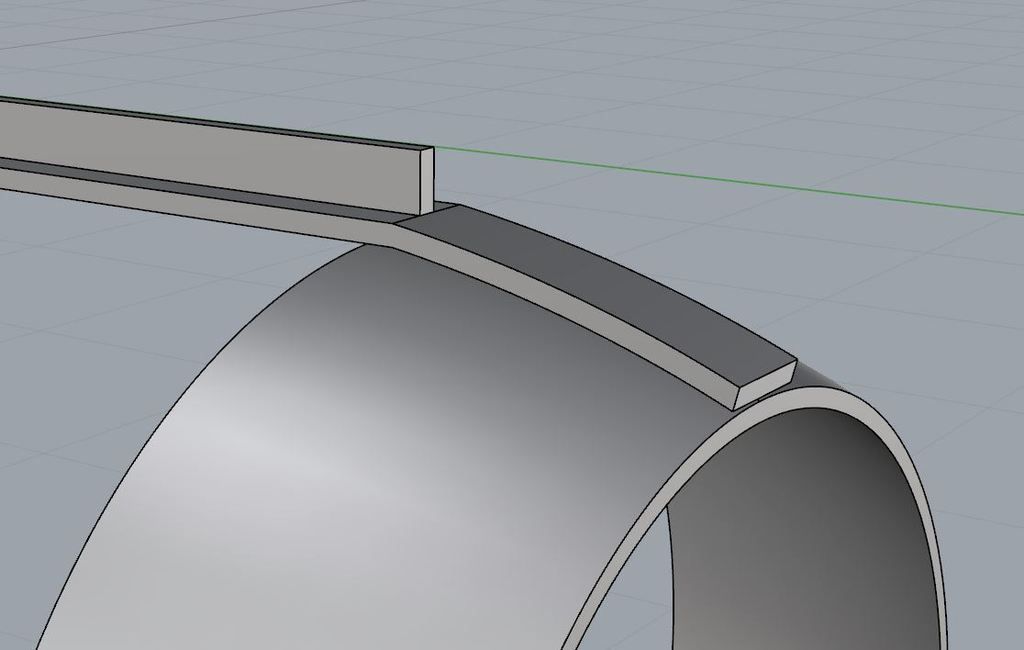

And a note - I'm redesigning the 3D printed nacelle cores to be less expensive to print using Shapeways. Will post when done.

http://www.therpf.com/showthread.php?t=258238&p=3938379#post3938379

And a note - I'm redesigning the 3D printed nacelle cores to be less expensive to print using Shapeways. Will post when done.

http://www.therpf.com/showthread.php?t=258238&p=3938379#post3938379